Author: Ganesh Mathiarasu

Published: 10 Feb 2023

Description: Machining our first rings

Machined Ring Experiments (Feb 6-10)

Since the structural design of the ring was drafted in CAD, it was time to manufacture it. The original plan involved machining the ring out of aluminium (A96061). The material was selected for its good mechanical properties such as durability, machinability and general aesthetics.

A combination of facing, turning, drilling, and boring operations were performed on a lathe and milling machine to form the ring from a 3-inch solid aluminium rod. Since the space inside the ring to fit the PCB tiles and battery was extremely constrained, it needed to be optimised and enlarged as much as possible.

Lathe in the student machine shop

Lathe in the student machine shop

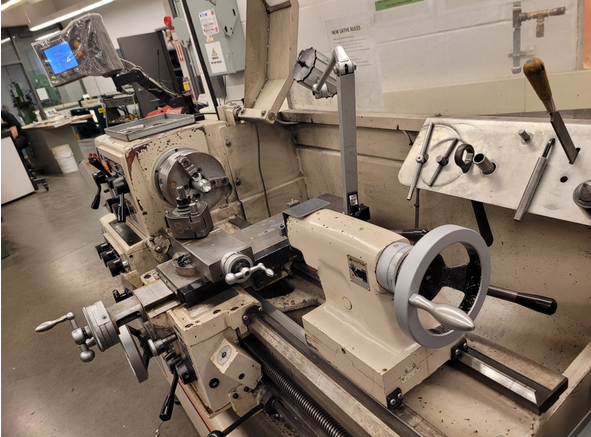

Therefore, an experiment was performed in order to determine the minimum thickness the walls of the ring could be machined down to until the structure showed signs of decreased strength. An iterative process was used to gradually decrease the thickness of a short cylinder until it crushed easily under a set of pliers. It was determined that a thickness of 1mm was the lowest we could machine it down to until it showed signs of damage from light pressure from pliers and drop tests.

One ring sample machined out of aluminum is shown below:

First metal ring

First metal ring

However, since there is some unused space within the ring, one area to explore would be to modify the shape of the ring from a regular cylinder to something more modern, and look into SLA resin printing for rapid prototyping and a more subdued and sleeker look.